No Room for Error:

IBW’s Precision Monitoring Strategy for Toronto’s Critical Rail Project

The Site

A segment of the Ontario Line in Downtown Toronto.

Challenge

Deliver a comprehensive scope of work—including pre-construction surveys, construction stakeout, volume calculations, implementation of a fully automated, high-precision monitoring system in a constrained and active rail corridor, real-time data management, as well as final as-built documentation for newly constructed tracks—all under complex field conditions.

Solution

Trimble S9 1" HP FineLock with Vision, Trimble 4D Control + T4D Web, Trimble SX10 Scanner, DJI Matrice 350 Drone, Trimble GEDO Track Measurement System.

Outcome

Improved accuracy, faster decisions, and significant time savings——delivered more efficiently and with less use of resources than projected.

Background

Founded in 1991, IBW has established itself as an innovator in geospatial services, offering an integrated suite of solutions for surveying, construction layout, and construction monitoring. With a reputation built on precision, adaptability, and technological leadership, IBW thrives on challenges that demand creative thinking and forward-looking execution. It is also known for hiring and developing top talent.

“We always strive for the best equipment and the best people,” says Pedro Sena, R&D Team Lead at IBW. “We push ourselves to be better with every project.” Their multi-disciplinary capabilities made IBW the ideal choice for a major Toronto rail infrastructure project requiring real-time, high-accuracy monitoring under tight constraints.

“We don’t want to be known as a company with just one specialty. We want to be a highly credible one-stop shop that brings deep expertise to every facet of any project we take on and commit to.”

Kevin Ertl O.L.S., B.Eng.

Partner and Business Development Manager at IBW

The Project: A High-Stakes Corridor Rebuild

IBW was engaged to support the early works phase of the Ontario Line project—part of a long-term investment to connect Exhibition/Ontario Place with the Toronto Science Centre via a new rapid transit system. The 1.2 km corridor needed to be raised by four feet to make room for two additional tracks. This required excavation as deep as 6m within just 20ft of live rail lines, plus the construction of thirteen T-wall retaining walls and three sections of 8m-tall secant walls.

“The tracks needed to be monitored 24/7—even during off-hours when they were in active use by commuter traffic,” Pedro explains. “Doing that manually wasn’t just impractical—it would’ve required far more manpower, increased the risk to crews working in live rail conditions, and slowed progress overall. We needed a smarter, cost-effective solution that could guarantee accuracy, improve safety, and minimize disruption.”

.jpg)

The Challenge: Uncompromising Precision Under Complex Conditions

IBW faced a range of site-specific challenges that demanded not only precision, but adaptability and efficiency. To meet project timelines and ensure safety, the team required reliable tools, smart workflows, and expert support to overcome the following critical hurdles:

-

Access & Setup

Working within a constrained corridor meant IBW needed coordinated access planning, support in navigating local permissions, and adaptive setup strategies to deal with vegetation, machinery, and limited work windows (9:30 a.m. to 2:30 p.m.) These limitations required the team to adapt by completing a significant portion of the work during night shifts. -

Frequent Interruptions

Live rail operations and concurrent construction activities made continuous work impossible. To stay efficient, the team needed smart workflows and tools that could minimize the time lost to repeated equipment setup, takedown, and relocation. -

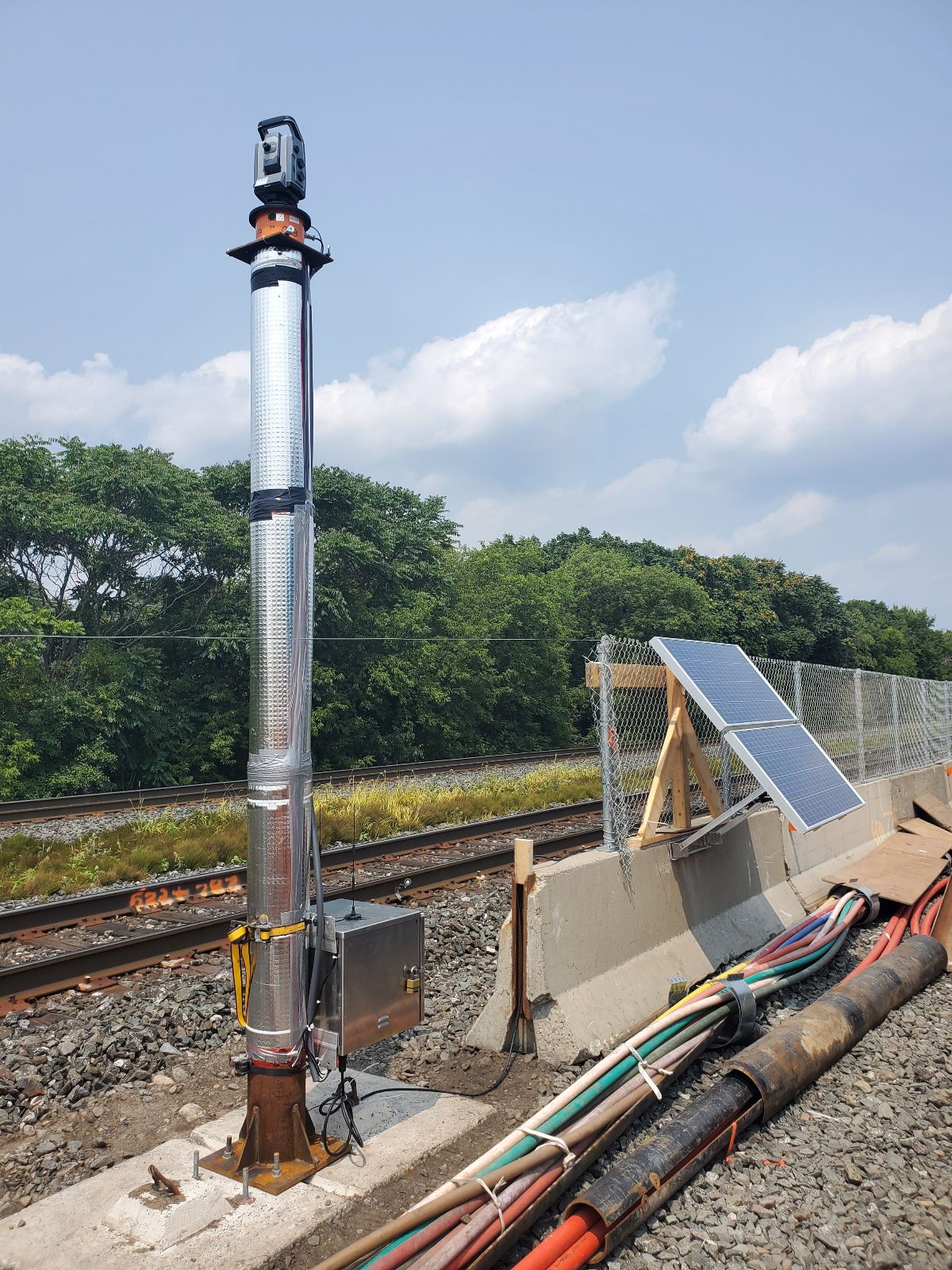

Power & Equipment

With limited sunlight on site, a reliable, self-sustaining power solution was essential. IBW also needed durable, field-ready gear and backup systems that could maintain performance under unpredictable site conditions. -

Environmental Factors

Heavy dust, vibration, and on-site movement created an environment where only ruggedized, low-maintenance equipment would succeed. A resilient system was needed to maintain data quality with minimal manual intervention.

.jpg)

-

Georeferencing & Line-of-Sight Limitations

Visual obstructions and the narrow work corridor made it challenging to establish a control network. IBW needed to get creative in establishing controls and securing access to neighboring properties. -

Data Complexity

Monitoring over 1,100 sensors required a streamlined system to group, filter, and process high volumes of data in real-time. IBW needed intuitive software with customizable alarm logic to distinguish meaningful movement patterns from routine fluctuations. -

Reporting & Coordination

With daily reviews and client updates required, IBW needed a system that could present data clearly and consistently, bridging field activity with office-based decision-making. Automated reporting and flexible visualization tools were crucial in saving time and keeping stakeholders informed. -

Training & Expertise

As this was IBW’s largest fully automated monitoring deployment, the team needed expert-led onboarding, practical training, and responsive support to confidently manage both hardware and software under real-world conditions.

The Solution: Multi-Tech Monitoring for Maximum Efficiency

IBW deployed a full suite of solutions sourced through Cansel, backed by expert consultation and technical support:

- Trimble S9 AMTS with VISION onboard camera technology – Enabled remote checks, target status inspection, efficient sensor setup, and precise tracking across all monitoring points.

- Solar-Powered Pedestals – Designed for off-grid operation with dual 300W solar panels and 200Ah battery backup per station.

- Settop M1 Modem – Provided automation of the total station and live communication with the office.

- Trimble 4D Control + T4D Web – Allowed real-time monitoring, customizable alerts, and automated reporting that helped IBW focus only on meaningful sensor activity.

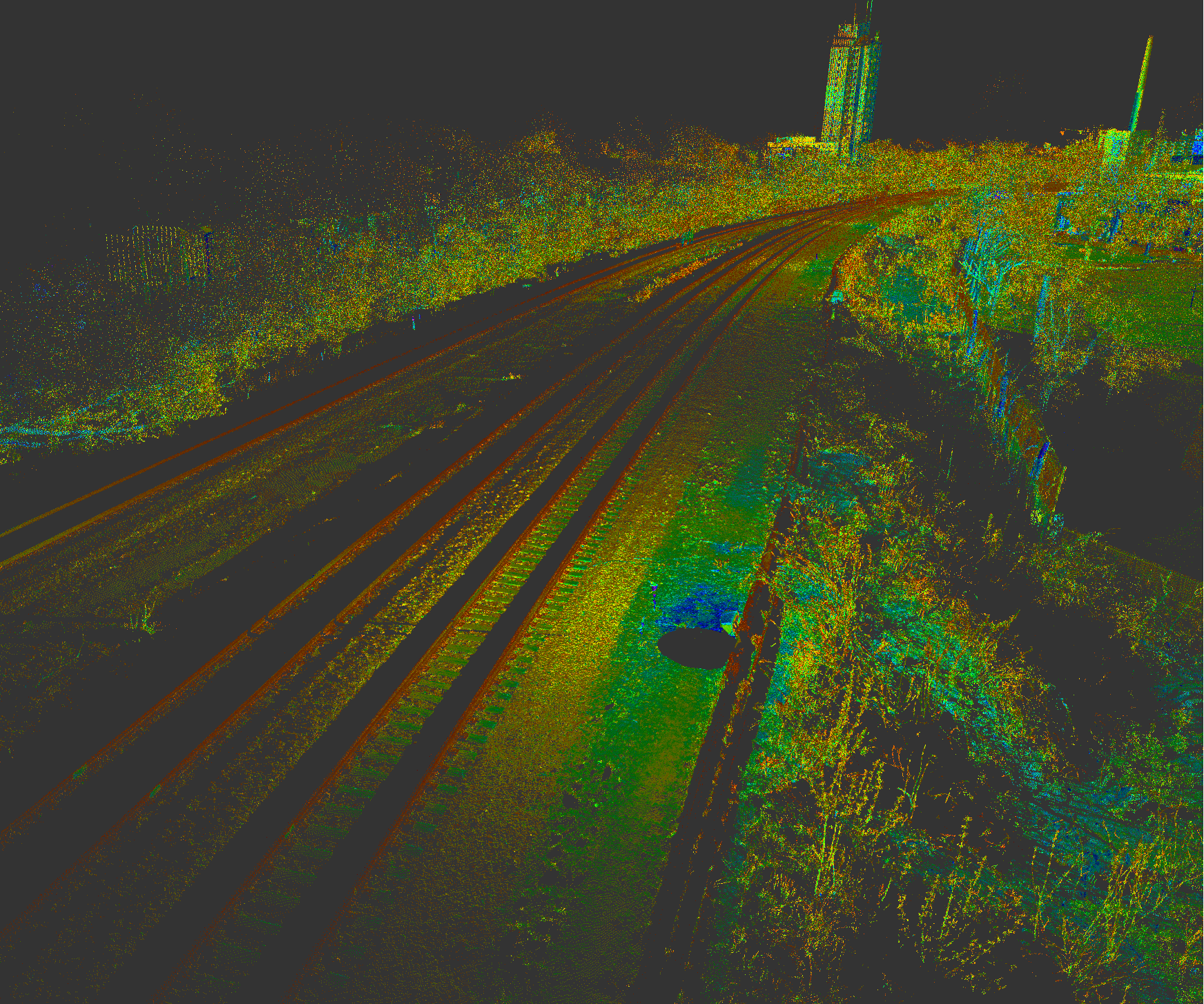

- Trimble SX10 Scanner – Captured detailed corridor data, combining high-resolution scans and images.

- DJI Matrice 350 Drone – Provided aerial overviews that gave both field and office teams greater situational awareness and supported faster, more informed decision-making throughout the project.

- Trimble GEDO Rail Trolley System – Efficient, rapid measurement for as-built surveys, stakeout, and rail track monitoring.

The Cansel Advantage: When Expertise Becomes an Extension of Your Team

“We didn’t just need equipment—we needed expert guidance for the system. Cansel showed us the options, explained the setup, and made sure we were fully ready.”

Pedro Sena

R&D Team Lead at IBW

From Bid to Breakthrough

IBW credits Cansel with helping from the earliest planning stages—including strategy sessions that supported their bid, and critical setup help once the job was awarded.

A Comprehensive Suite of Solutions

With one of the most advanced portfolios of geospatial technology in the industry, Cansel doesn’t just offer tools—they offer insight. As experts in integrated workflows and a wide range of leading solutions—such as Trimble—they don’t just recommend a product; they explain why it fits, how it works, and how it addresses the challenge at hand. For IBW, this meant a carefully selected, multi-technology strategy designed to maximize efficiency, accuracy, and value across every phase of the project.

As a one-stop shop themselves, IBW especially valued that, with Cansel, they didn’t need to go elsewhere to complete the workflow. The right hardware was only part of the equation—Cansel also provided the software expertise to fully unlock its potential. From licensing to setup to hands-on training, their team knew how to match the right applications with the right tools to keep things running smoothly in both the field and the office.

Dependable Support When It Counted Most

True to its Field-to-Finish commitment, Cansel delivered on its service promise. From on-site training to hands-on troubleshooting, their team was always available—ready to connect, advise, and step in when needed. That level of responsiveness gave IBW the confidence that they were never navigating challenges alone.

“They had our back the whole way through. Cansel stuck with us until we solved the challenge, and our team could run with the solution.” - Kevin Ertl

The Results: Accurate, Scalable, and Ready for What’s Next

- Massive Time Savings – Over 1,100 prisms monitored every hour with minimal site visits.

- Reliable Accuracy, Minimal Upkeep – Aside from occasional prism maintenance, the system delivered accurate data 24/7 via a web portal and automated scheduled reports.

- Meaningful Alerts Only – Smart alarm configuration eliminated false notifications, focusing attention where it mattered.

- Prepared for the Future – Early challenges have become lessons that now enable IBW to anticipate seasonal challenges and respond proactively.

- Better Data, Better Decisions – The combination of these technologies and data points—including aerial views, corridor scans, and sensor feedback—enabled the IBW team to gain critical insight, make informed decisions, and deliver greater value to their client.

"We were able to get more data, better results, and deliver a higher-quality product to the client,” says Pedro. “And we were able to do it faster than conventional methods."

“It’s genuinely inspiring to work alongside a company like IBW Surveyors, who continuously push to raise the industry standard by investing in both their people and cutting-edge technology,” says Adam Tyler, Key Accounts Manager, Survey & Engineering at Cansel. “Our ongoing collaboration with their ownership, administrative, and project management leaders allows us to better understand their evolving business needs and deliver well-supported, practical solutions. Being part of that progress is a privilege—for me and for the entire Cansel team—and we’re excited for what’s ahead.”

IBW serves construction and infrastructure projects across Ontario, Canada. Learn more about their services at ibwsurveyors.com. You may also reach out to Kevin Ertl or Pedro Sena.

The Cansel Group creates success stories to proudly showcase the achievements of our customers who have trusted us as their partner and relied on our expertise to provide the best, most advanced solutions for the job.