What Is a Robotic Total Station (and Why Surveyors Love It)

In the fast-paced world of modern surveying, precision, speed, and efficiency are everything, and that’s exactly why robotic total stations have become a staple on job sites around the globe.

These advanced instruments combine multiple functions into a single, powerful tool. But what really sets them apart is their ability to be operated by just one person, cutting down on crew size without sacrificing accuracy.

Whether you're laying out a complex construction site, mapping terrain, or conducting as-built surveys, robotic total stations streamline workflows, reduce errors, and improve productivity. In this article, we’ll break down what a robotic total station is, how it works, and why surveyors consistently rank it as one of the most essential tools in their toolkit.

What is a Robotic Total Station?

A Robotic Total Station (RTS) is an advanced surveying instrument that combines electronic distance measurement (EDM) with an electronic theodolite, allowing for precise angle and distance measurements.

Unlike traditional total stations, an RTS is equipped with motorized components and software that enable it to automatically track and follow a prism, typically mounted on a survey rod. This automation significantly enhances efficiency and accuracy in data collection, reducing human error as well as the need for manual adjustments. This allows a single operator to conduct surveys that would normally require a team.

The primary goal of a Robotic Total Station is to streamline the surveying process by providing a high level of precision and ease of use. It is widely used in construction, engineering, and geospatial applications for tasks such as:

- Topographic surveys

- Layout work

- Monitoring of structures.

By leveraging advanced technology, RTS devices facilitate faster data collection and processing, leading to cost savings and improved project timelines.

In the context of search intent, individuals seeking information about Robotic Total Stations are often interested in understanding their functionalities, benefits, and applications.

The network of meaning surrounding RTS includes concepts such as automation, precision, efficiency, and technological advancement in surveying practices. As such, an RTS represents a significant evolution in the field of surveying, offering a blend of traditional measurement techniques with modern automation to meet the demands of contemporary projects.

How does a Robotic Total Station work?

A Robotic Total Station (RTS) operates through a blend of advanced components and systems that enable automated surveying. At its core, the RTS includes a total station unit equipped with motorized mechanisms for precise movement and alignment. This unit functions alongside a robotic control system that manages the instrument's operations, such as tracking and measuring, through sophisticated software.

Total station unit

The total station unit is the heart of the RTS, integrating an electronic theodolite with electronic distance measurement (EDM) technology. This combination allows for precise angle and distance measurements. The unit is equipped with various sensors that contribute to its accuracy and functionality.

Below is a detailed table of the components and their roles:

| Component | Function | Contribution to Precision |

| EDM Technology | Measures distances using laser or infrared | Ensures accurate distance measurements |

| Motorized Mechanisms | Automates movement and alignment | Enhances precision and reduces manual errors |

| Optical Sensors | Detects target position and alignment | Improves targeting accuracy |

| Reflective Prism | Serves as a target for measurements | Ensures consistent data capture |

Robotic control system

The robotic control system orchestrates the RTS's operations, utilizing sophisticated software to automate tasks such as tracking and target alignment. This system allows for seamless surveying with minimal manual intervention. Key tasks automated by the system include:

- Automated Tracking: Continuously follows the target, reducing the need for manual adjustments.

- Target Alignment: Ensures precise alignment with the target, enhancing measurement accuracy.

- Data Processing: Analyzes data in real-time, providing immediate feedback and results.

Some stations like the Trimble SX12 HaLow Scanning Total Station can combine scanning, imaging and surveying into one powerful solution, so you only need one instrument on the job site to perform all your data capture. Apart from being able to automate key tasks, consider looking for an RTS that can help you multi-task with only one device.

Communication interface

The communication interface is essential for facilitating real-time data exchange between the RTS and the operator's device. This interface supports remote operation via wireless connections, such as Bluetooth or Wi-Fi, allowing a single operator to control the device from a distance. The table below details the wireless technologies used and their roles:

| Wireless Technology | Role in Communication | Benefits |

| Bluetooth | Short-range communication with operator's device | Enables quick and easy setup |

| Wi-Fi | Long-range data transfer and remote operation | Higher data bandwidth |

| Radio Frequency | Provides robust communication in challenging areas | Ensures reliable connection at a longer range |

By integrating these elements, a Robotic Total Station provides a seamless and efficient surveying experience, meeting the needs of users seeking precision and automation in surveying technology.

Why do surveyors prefer Robotic Total Stations?

Surveyors prefer Robotic Total Stations (RTS) for their ability to enhance efficiency and accuracy in data collection. An RTS allows for faster setup times, reducing the time and effort needed to complete surveying tasks. This capability is especially beneficial in complex projects where speed and precision are critical.

Additionally, the RTS provides high-resolution measurements while minimizing human error, ensuring that the data collected is both accurate and reliable. Surveyors value the labor reduction offered by the RTS, as its single-operator capability and remote operation benefits streamline workflows and decrease the need for multiple personnel on-site.

Overall, the RTS offers a combination of efficiency, precision, and cost-effectiveness that aligns with the needs of modern surveying projects, making it a preferred choice among professionals. By leveraging these advantages, surveyors can achieve more consistent and high-quality results, meeting the demands of various applications with confidence.

Teams looking to optimize their project’s workflow and data collection should consider the Trimble SX12 HaLow Scanning Total Station. With fully integrated field and office software workflows, as well as 1” angular accuracy, this total station saves you time by producing extremely clean point clouds and capturing detail in key areas with its surgically precise scanner.

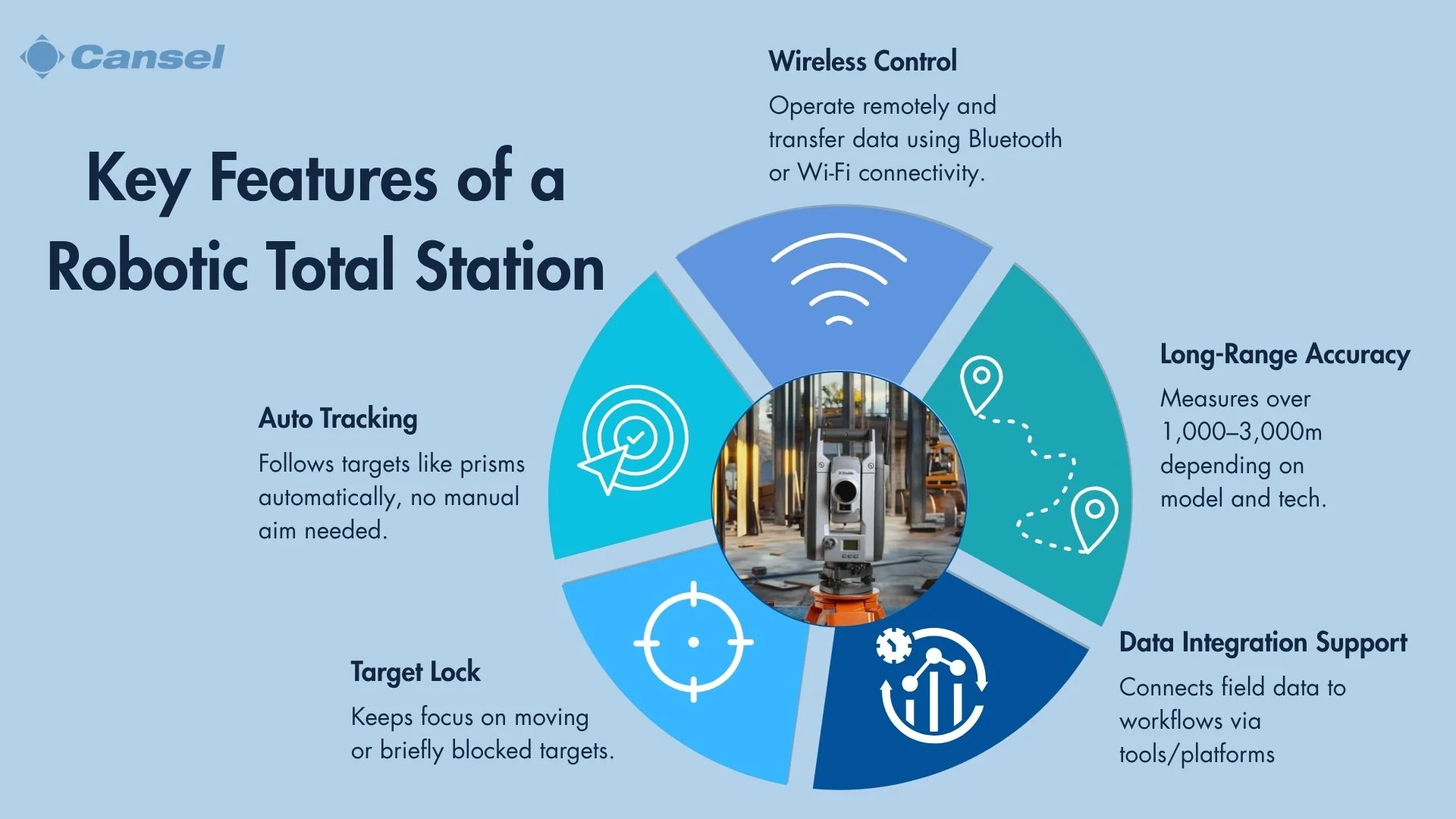

What are the key features of a Robotic Total Station?

Robotic Total Stations (RTS) are equipped with several key features that enhance their functionality and appeal to surveyors. One of the standout features is automated tracking, which allows the RTS to follow a target, typically a prism, without manual intervention. This feature is complemented by target lock technology, ensuring the instrument maintains focus on the target, even if it moves or is temporarily obstructed.

Dynamic tracking capabilities further improve the RTS's efficiency by allowing it to adjust to changes in the target's position in real time. The remote operation and wireless control capabilities enable surveyors to manage the RTS from a distance, offering flexibility and convenience, particularly in challenging environments. Additionally, the RTS boasts long-range capabilities, enabling it to perform accurate measurements over considerable distances.

While RTS systems offer powerful data integration features, connecting field data to CAD environments or broader workflows isn’t always seamless right out of the box. That’s where platforms like Can-Flow come in, providing a field-to-finish efficiency platform that standardizes workflows, automates key processes, and streamlines the transfer of survey data between field teams, project managers, and engineers.

Wireless control

Wireless control enhances the user experience by enabling seamless communication between the RTS and the operator's device. This feature supports efficient data transfer and instrument management, streamlining the surveying workflow. Examples of wireless technologies used include Bluetooth and Wi-Fi, which facilitate remote operation and real-time data exchange, allowing surveyors to control the RTS from a distance.

Long-range capabilities

Modern robotic total stations, like the Trimble S9 or S7, can measure distances of up to 5,000 meters with a prism and over 800 meters without one (in reflectorless mode), making them ideal for large infrastructure, transportation corridors, and topographic surveys.

These systems maintain millimeter accuracy even at long ranges, enabling users to stake out or collect data from a distance without moving the instrument frequently, reducing downtime and increasing operational efficiency.

Additionally, long-range autolock and target tracking allow the RTS to automatically follow a prism as it moves across the site, even when obstacles or elevation changes are present. This is especially valuable in uneven or obstructed terrain where line-of-sight can be a challenge, such as busy traffic intersections or construction sites.

With robust signal integrity, extended range, and consistent accuracy, the long-range performance of robotic total stations ensures that even the most complex, large-scale projects can be completed with speed and confidence.

How does a Robotic Total Station enhance surveying projects?

Robotic Total Stations (RTS) enhance surveying projects by providing significant time savings and improving overall project efficiency. Their ability to perform quick data acquisition allows surveyors to gather comprehensive datasets in a shorter period, which is crucial for meeting tight project deadlines. This efficiency is further supported by streamlined workflows that reduce the complexity and duration of surveying tasks.

The cost-effectiveness of an RTS is another major advantage, as it leads to reduced manpower costs and lower operational expenses. By enabling a single operator to manage the entire surveying process, the RTS minimizes the need for large teams, thus cutting labor costs.

Additionally, the precision and reliability of the data collected by an RTS result in improved data quality and consistent accuracy, which are essential for generating reliable project outcomes. For example, the Trimble S Series ensures accurate pointing and measurements for your project as it actively corrects for unwanted movements like winds and sinkage.

Overall, the integration of an RTS into surveying projects provides a comprehensive solution that aligns with the needs of professionals seeking efficiency, accuracy, and cost savings. By leveraging these benefits, surveyors can deliver high-quality results that meet the demands of modern surveying applications.

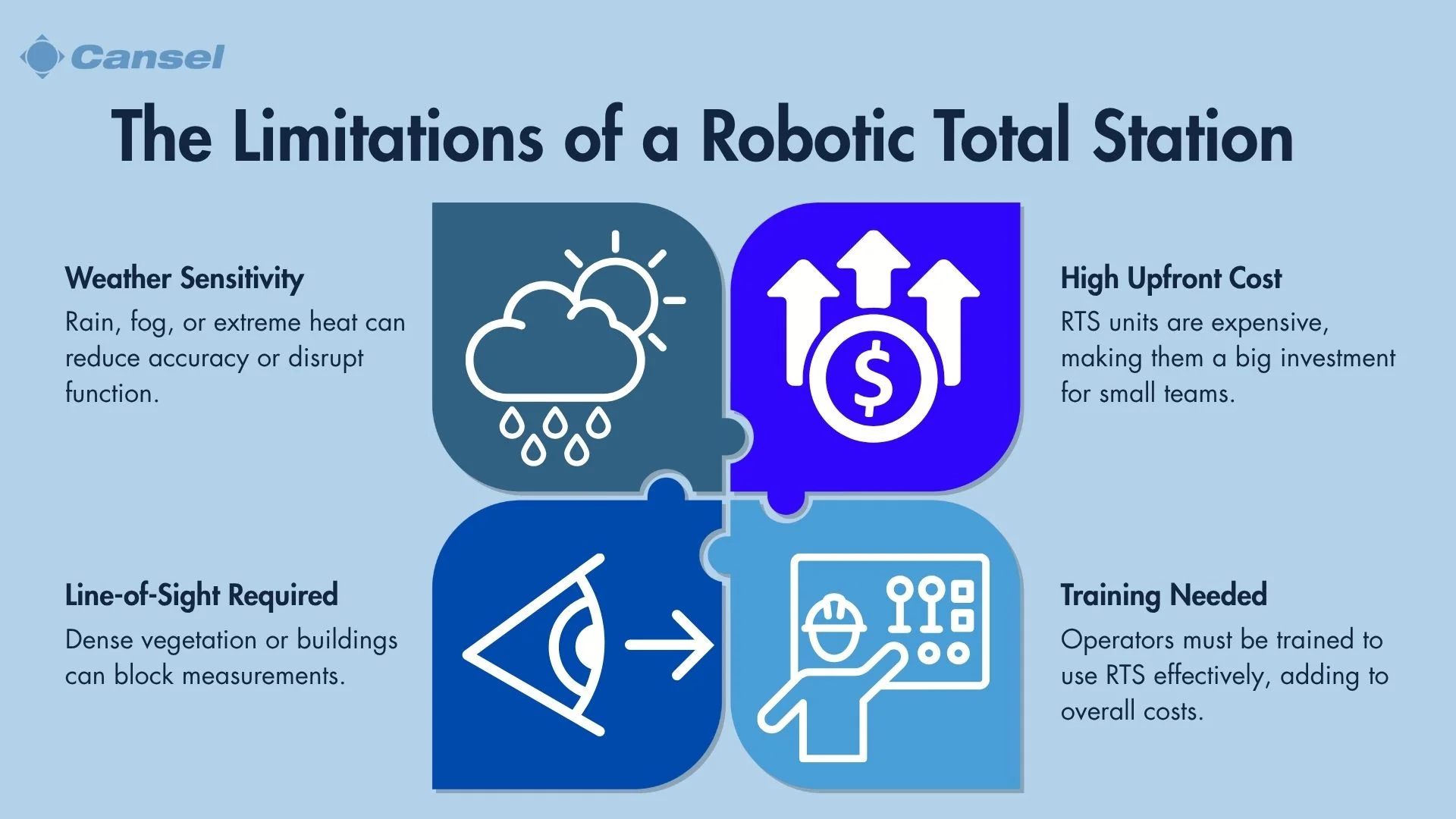

What are the limitations of using a Robotic Total Station?

While Robotic Total Stations (RTS) offer numerous advantages, they also come with certain limitations that surveyors must consider. One significant constraint is their environmental sensitivity, as RTS devices can be affected by weather conditions that may impact performance and accuracy.

Another key limitation is the requirement for a clear line of sight between the instrument and the target. This can pose challenges in environments with dense vegetation, moving equipment, or complex urban infrastructure that blocks visibility.

A further consideration is the cost of ownership. RTS units require a substantial upfront investment, which may be difficult for smaller firms or startups to manage. To help overcome this, many businesses turn to equipment rental such as the Cansel Elite Survey Equipment Placement Program, which is a flexible 12–36 month alternative that provides access to high-performance RTS equipment without the burden of full ownership.

In addition, while RTS technology is powerful, it’s most effective in the hands of a well-trained operator. Cansel supports this with a range of expert-led training options. Rather than an added cost, training is a smart investment that drives ROI by reducing rework, speeding up workflows, and increasing field confidence.

Training expenses

In addition to the cost of the equipment, training is a critical investment for maximizing the value of a robotic total station. While some RTS systems have very user-friendly interfaces, most operators still require structured training to use these tools to their full potential.

This is where Cansel adds real value. Their comprehensive training programs, ranging from in-depth classroom sessions and hands-on field instruction to fully customized, project-specific courses, are designed to help teams master both the technology and its application in real-world workflows.

By training with Cansel, companies don’t just improve software knowledge; they improve productivity, reduce mistakes, and accelerate project timelines. The result is a more capable, confident team and a stronger return on investment in your RTS technology.

Environmental constraints

Robotic Total Stations (RTS) are subject to various environmental constraints that can impact their performance. These constraints often dictate the conditions under which the RTS can operate effectively, influencing the planning and execution of surveying tasks.

| Environmental Factor | Impact on RTS Performance | How Trimble RTS Mitigates These Factors |

| Heavy Rain | Reduces visibility and range of operation | All RTS models feature IP65 rating, providing protection against heavy rain and dust |

| Fog | Obstructs line of sight and reduces range of operation | RTS systems with ActiveTrack/SurePoint technology improve auto-tracking in low-contrast conditions |

| Extreme Temperatures | Affects electronic components, potentially leading to malfunctions | RTS units such as the Trimble S7 Total Station operate reliably in –20 °C to +50 °C (–4 °F to 122 °F) environments |

| Dense Vegetation | Blocks line of sight, hindering accurate measurements | Long-range DR Plus EDM (up to 5,500 m) allows measuring from cleared vantage points |

| Urban Structures | Causes signal reflection and obstruction | 30× optics and video-assisted workflows (Trimble VISION) enable precise aiming around obstructions. |

How is the future of surveying impacted by Robotic Total Stations?

The future of surveying is significantly influenced by Robotic Total Stations (RTS) through their integration of cutting-edge technologies and automation. As RTS devices continue to evolve, they are expected to incorporate technological advancements that enhance their capabilities and expand their applications. This evolution is driven by the increasing demand for more efficient, precise, and versatile surveying solutions.

Today, RTS can already be used to guide robots that paint lines on construction sites, track water-based drones that collect depth measurements and give position to rail trolleys for accurate rail track geometry data. Combined with IoT devices, they can perform continuous, unattended data collection and real-time environmental monitoring. Future advancement in automation will surely create more applications of RTS on our construction sites.

Thanks to the strides made (and continuing to be made) in RTS technology, a solo operator can now complete tasks that once required multiple team members, allowing firms to allocate human resources more strategically. This not only reduces labor costs but also opens the door for more agile project deployment in the future.